Turning old clothes into high-end building materials

Researchers at UNSW Sydney have developed an effective process to turn old clothing and textiles into high-quality building products such as flat panels.

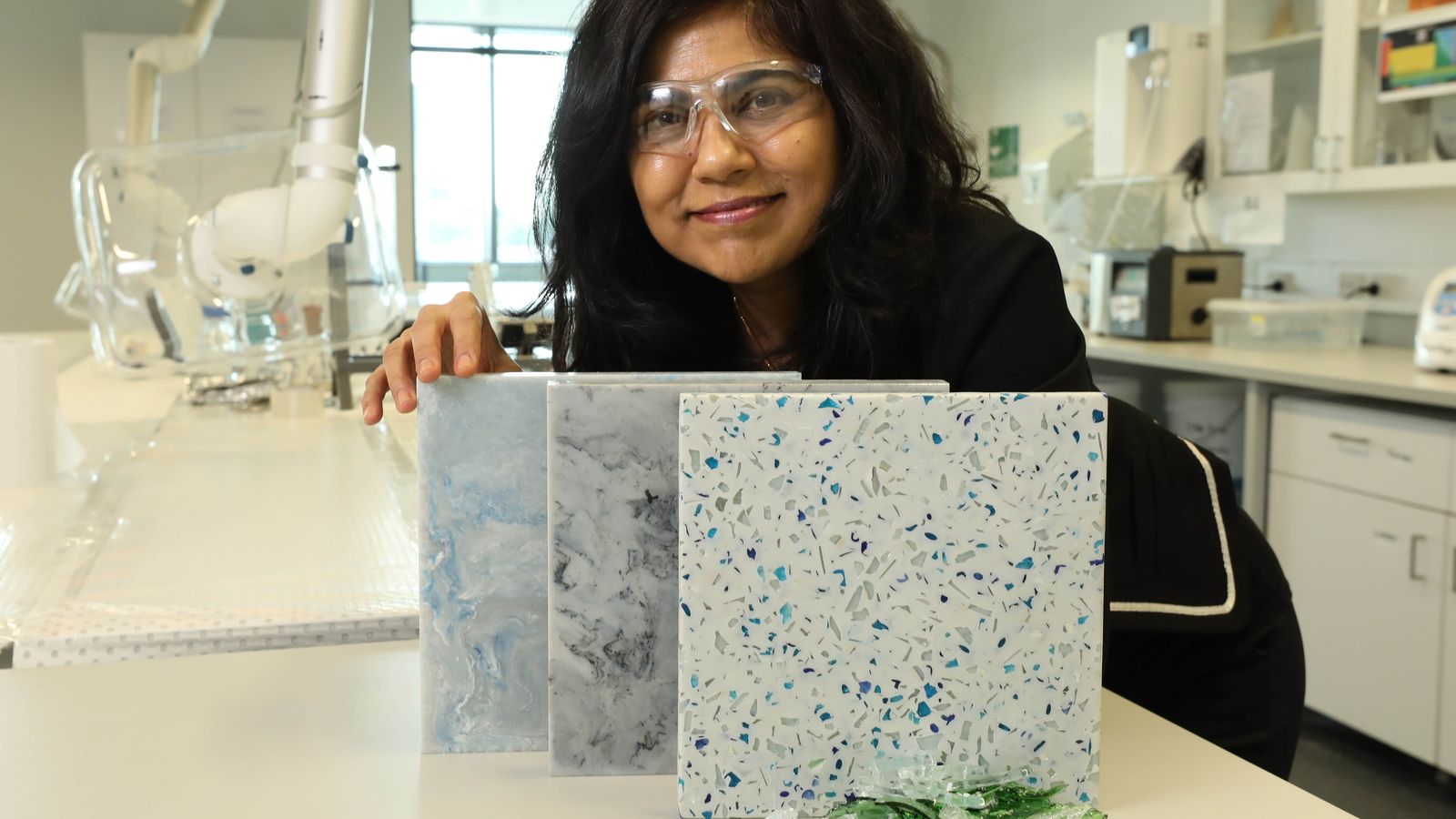

These high-end composite products can have a wood veneer look or a ceramic-style finish and were lab tested for qualities such as fire and water resistance, flexibility, acoustic and load-bearing capabilities but have not undergone any formal regulatory assessment.

This follows a separate but related research exercise that converted used glass into high-quality ceramics suitable for benchtops and tiles in kitchens and bathrooms that can come in all sort of sizes, colours and finishes.

Researchers led by Professor Veena Sahajwalla, Director of UNSW’s Centre for Sustainable Materials Research and Technology (SMaRT), have been scientifically reforming common waste items using prototype technology developed for a laboratory-scale ‘green microfactory’ to be launched in 2019.

Fashion has a lot to answer for

"Clothing is now one of the biggest consumer waste streams, with 92 million tons estimated to be thrown out in a year": read Veena Sahajwalla's opinion piece in The Sydney Morning Herald.

“These newly published results of the wonderful products developed from waste come as an effort to find ways to reduce waste and address our unsustainable landfill problems, which all countries are experiencing,” she said.

“It could be said that consumers and the fashion industry have a lot to answer for, given that clothing is now one of the biggest consumer waste streams, with 92 million tons estimated to be thrown out a year globally. The clothing and textiles industry is the second most polluting sector in the world, accounting for 10% of the world's total carbon emissions.”

Microfactory

Reforming old clothing and mixed waste glass into various high-quality building products represents a new way to convert low-value waste into high-value products and materials. This new work builds on technology which can recover and reform materials from electronic waste from UNSW’s demonstration e-waste microfactory launched in April 2018.

Professor Sahajwalla said that when considering that the population growth trend is expected to jump from a current world population of 7.6 billion to 9.8 billion by 2050, the earth’s resources need to be preserved and re-used rather than put in landfill or incinerated.

“There is much that can be done right now given that scientifically-developed, proven methods are currently available through our green microfactory technology,” she said. “Rather than export our rubbish overseas and to create more land fill, green microfactory technology has the potential to enable small- and large-scale creation of newly manufactured products instead.”

While the textiles materials tested exceptional well in labs to mechanical performance properties including strength, flexibility and resistance, further lab testing is required to explore these properties ahead of consideration of applying for any formal assessment against construction regulations.

Professor Sahajwalla said green microfactories can not only produce high performance materials and products, they eliminate the necessity of expensive machinery, save on the extraction from the environment of yet more natural materials, and reduce the waste burden.

Recent UNSW consumer research showed most people did not believe the waste materials they put out in their recycle bins is actually recycled but ends up in landfill, with 91.7% of people saying is it very or somewhat important for Australia to invest in technology to ‘reform’ most common waste to reduce landfill.

A major impediment to new solutions to the waste problem, Professor Sahajwalla said, was getting the technology commercialised and into the market, and without government incentives to attract industry and change behaviour progress would be slow.

Glass stockpiles alone amount to more than one million tonnes per year nationally. In total, Australia produces nearly 65 million tonnes of industrial and domestic solid waste each year, but it is now cheaper to import than recycle glass here. About 60 per cent of waste is reportedly recycled but much of this is low value.

E-waste microfactory background

The NSW Environment Minister launched the world’s first demonstration e-waste microfactory in April this year.

This showcases a process developed by the UNSW SMaRT Centre which transforms the components of discarded electronic items like mobile phones, laptops and printers in to new and reusable materials that can then be used to manufacture high value products such as high value metal alloys, carbon and products such as 3D printer filament.

Our e-waste mircofactory involves a number of small machines for this process and they fit into a small room. The discarded electronic devices and items are first placed into a module to break them down. The next module may involve a special robot to extract useful parts.

Another module uses a small furnace to separate the metalic parts into valuable materials, while another one reforms the plastic into filament suitable for 3D printing.

UNSW is now finalising a second demonstration green microfactory which converts glass, plastics and other waste materials in to value-added products. Mixed waste glass is used to create engineered stone products. Wood, plastic and textile waste is used to create valuable insulation and building panels.

UNSW, through its ARC Green Manufacturing Hub, has developed this technology with support from the Australian Research Council and is in partnership with several businesses and organisations including recycler TES and manufacturer Moly-Cop. And through the Commonwealth funded CRC-P initiative, SMaRT is partnering with Dresden, which makes spectacles, in the use of recycled plastics.

This article was originally published on the UNSW Newsroom. Text by Stuart Snell.

Images: Professor Veena Sahajwalla, Director of UNSW’s Centre for Sustainable Materials Research and Technology (SMaRT), with glass waste ceramic tiles. Building panels made from unwanted clothing. Photos: Courtesy of UNSW Newsroom.